R&D

Design studies and development of new machines.

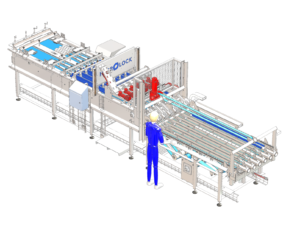

As a specialist in mechanical and thermodynamics systems, Hydrolock is supported by a strong engineering department equipped with state of the art CAD tools. Our automation team also develops programs using the most renowned PLC’s and software on the global market.

Factory manufacturing

HYDROLOCK sterilizers are manufactured in our factory of “Le Bignon”, in the suburb of Nantes in France. The machines are fully assembled and mechanically tested before being shipped. This allows time saving for re-assembly and start up on site. F.A.T. (Factory Acceptance Tests ) are organized with customers before machine shipping.

Maintenance and Spare Parts

Our supervisors and automation engineers are travelling wordwide to assist our customers during machine installation, retrofits and maintenance. Hydrolock developed a network of partners close to our customers to provide local assistance.

HYDROLOCK has a storage of specific parts in Nantes France ready to be shipped all over the world. A remote access to the production unit is available in order to help our clients diagnosis in case of failure on a sterilization line.

PROCESS DEVELOPMENT

HYDROLOCK’s laboratory is available to develop recipes and new products using the Hydrolock sterilizers, in order to determine and confirm the optimum parameters for the packaging and products.

Our pilot is able to simulate all kinds of Hydrolock, Steriflex, Steritherm, and to compare it to batch processes in order to demonstrate advantages.